DC TDI

Photon counting in battery inspection - Varex Imaging

By using high quality X-ray imaging technology for battery inspection during the key steps within the non-destructing quality control protocols, the novel inspection technique can help confirm both safety compliance and quality assurance requirements are met as established by the battery manufacturer.

Whether small or large, batteries are typically designed using ultra-thin, alternating layers of cathode, electrolyte, and anode, with insulation to separate the layers and prevent potential short circuits. Small batteries, like those used in smart devices, usually have 20-50 layers, while larger batteries, like those used in electric vehicles, tend to have upwards of 200-250 layers. With batteries having so many alternating layers, each with a thickness of between 10 and 150 μm, high precision imaging detectors are required for battery inspection.

DC-TDI X-ray Detector in 2D Battery Inspection

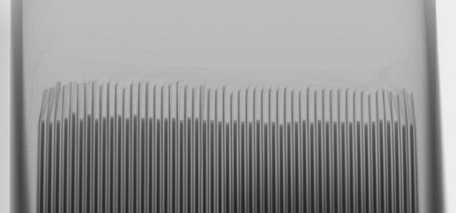

Our DC-TDI detector can provide high speed pre-scan imaging of significant anomalies during in-line inspection of stacked batteries. Using this method, potential malfunctions that can cause defects in the batteries, the anode-cathode offsets in this case, can be quickly identified.

For this 2D inspection method, the parallax effect of the stacked layers is reduced to a minimum possible level by keeping the scanning direct at a 90-degree angle to the anode/cathode layers so that every layer is vertical to the line scanner.

A battery inspection system requires geometric magnification to be able to distinguish the layers inside a battery which means that the focal spot of the X-ray source needs to be 15-40µm in size, and in some cases a bit smaller. Microfocal X-ray sources have limited power which in turn requires an efficient detector. Typically, the efficiency of a detector is improved by increasing the number of pixel lines to be able to capture a larger part of the X-ray beam. This, however, causes a more severe parallax issue disturbing the inspection.

High speed battery inspection is key as battery technology advances

Over the past few years, the market for electric vehicles has expanded by leaps and bounds as these vehicles have become more practical and mainstream. With expanded battery capacities and fast charging capabilities being developed, battery manufacturers must continue to adapt to keep in step with new challenges. Our Direct Conversion engineers will continue to work closely with battery manufacturers to provide high speed and accurate X-ray detectors as the manufacturers work to ramp up production.